At MP Industries Corp, we specialize in delivering precision-crafted components through cutting-edge CNC machining solutions. Our state-of-the-art facilities and experienced team are dedicated to meeting the diverse needs of industries such as automotive, aerospace, medical, and manufacturing.

We are also equipped with a wide range of welding equipment for fabricating or assembling components through MIG, TIG, pulse, and GMAW or wire feed welding. In addition, an Electro Arc tap burner is used for safely removing broken drills or taps during fabrication. Our extensive welding capabilities enable us to assemble aluminum, stainless steel, and mild steel sheets with thicknesses up to 0.50″.

In addition to Machining, welding and fabrication, MP Industries offers value added services such as anodizing, notching, painting, plating, and powder coating through subcontract suppliers and design services. Through vendor audit programs, we closely monitor the performance of all our subcontract suppliers.

Our Work Portfolio

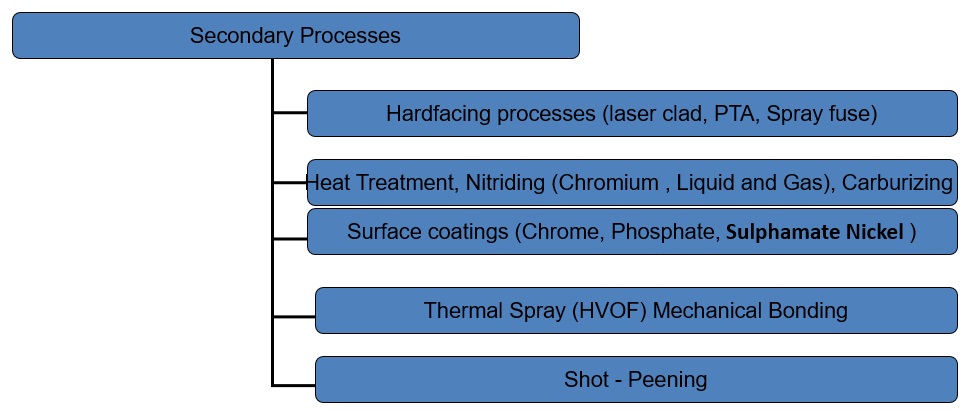

MP Industries has secured long term relationships with a variety of highly qualified vendors allowing us to provide the following processes, and more:

CNC Machining

Precision machining with state-of-the-art CNC equipment for complex geometries and tight tolerances

- Multi-axis CNC turning and milling

- Precision tolerances to ±0.0001"

- Complex part geometries

- Production and prototype quantities

Welding Services

Comprehensive welding capabilities for various materials and applications

- MIG, TIG, pulse welding

- GMAW or wire feed welding

- Aluminum, stainless steel, mild steel

- Sheet thicknesses up to 0.50"

Metal Fabrication

Custom fabrication services from design to finished components

- Sheet metal forming and cutting

- Custom assemblies and structures

- Prototype to production volumes

- Quality inspection and testing

Value Added Services

Complete finishing and specialized processes through trusted partners

- Anodizing and surface treatments

- Painting and powder coating

- Plating and finishing services

- Design and engineering support

Quality Assurance & Process Control

Our commitment to quality is demonstrated through rigorous process controls and vendor partnerships. We maintain strict quality standards throughout all manufacturing processes and continuously monitor our subcontract suppliers through comprehensive vendor audit programs.